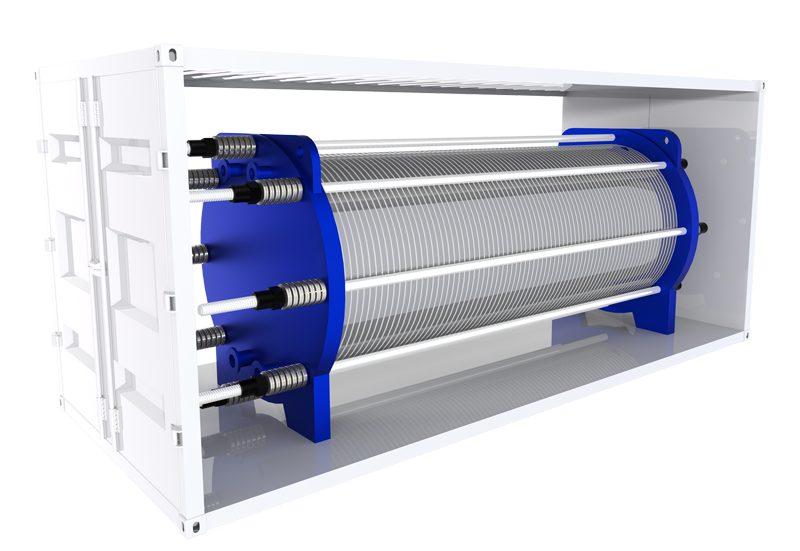

Hydrogen Generating Plant by Water Electrolysis

VIEW MORE+Angstrom Advanced is the leading supplier of Hydrogen Generators for refinery, petrochemical and other industrial applications. Our services for Hydrogen Generating Plant projects typically include conceptual design, detailed engineering, procurement, fabrication, construction, start-up and operational training. We provide a lump-sum, turnkey solution, handling everything from concept to start-up with our own resources whenever possible.

The control cabinet is the key part of the entire monitoring system to maintain the safety and stable running of the Hydrogen Generator. The regulating of operating pressure of hydrogen generator ensures that the generator will be able to operate under the required working pressure. The control arithmetic used in this system is PID algorithm. The pressure transmitter samples the system pressure and is transferred to PLC through the safety barrier to compare with the working pressure set-point, the arithmetic result gained from PLC will be converted to be standard signal of 4~20mA DC from the analogue output module and then into a standard gas signal of 0.02~0.1Mpa through the electric-pneumatic converter, and the pneumatic signal controls the opening of pneumatic regulating valve so that the operating pressure is to be kept at the set-point value.

Angstrom Advanced hydrogen control system allows the plant to actively control generator parameters.

Angstrom hydrogen control systems integrated into the hydrogen generator automatically controls purity and dew point. Actively controlling hydrogen at optimum levels in the hydrogen generator will:

- Warn the user of excess limit monitored parameters

- Optimize efficiency

- Maximize generator capacity

- Provide safe hydrogen supply

- Automatically cut off power to rectifier in case of excess pressure is reached

-

-

Hydrogen Generator by Natural Gas Steam Reforming

VIEW MORE+ -

Hydrogen Generation Plant by Methanol

VIEW MORE+ -

Hydrogen Generator by Ammonia Decomposition with Purifying System

VIEW MORE+ -

Pressure Swing Adsorption Hydrogen Generator with Purifying

VIEW MORE+